A flexible intermediate bulk container (FIBC) is an industrial container made of a flexible fabric designed for storing and transporting dry, flowable products. These large, sturdy bags offer numerous benefits in terms of storage, transportation, and handling of bulk materials. However, it is crucial to understand that not all FIBCs are created equal. Different types of FIBCs exist, each designed to meet specific requirements and address unique challenges. Keep reading to learn the differences between the five styles and which type may be best suited to your bulk packaging needs.

Top Different Types of FIBC Bags

U-Panel Bulk Bags

U-panel bags are constructed with three main body components: one piece that runs the full length of the bag forming the bottom and two sides (the “U”) and two additional pieces of fabric sewn between the “U” on two sides (the “panels”).

Generally, U-panel bags will maintain a square shape when filled, especially with the addition of internal baffles. U-panel bags are an industry standard and the most popular type of construction.

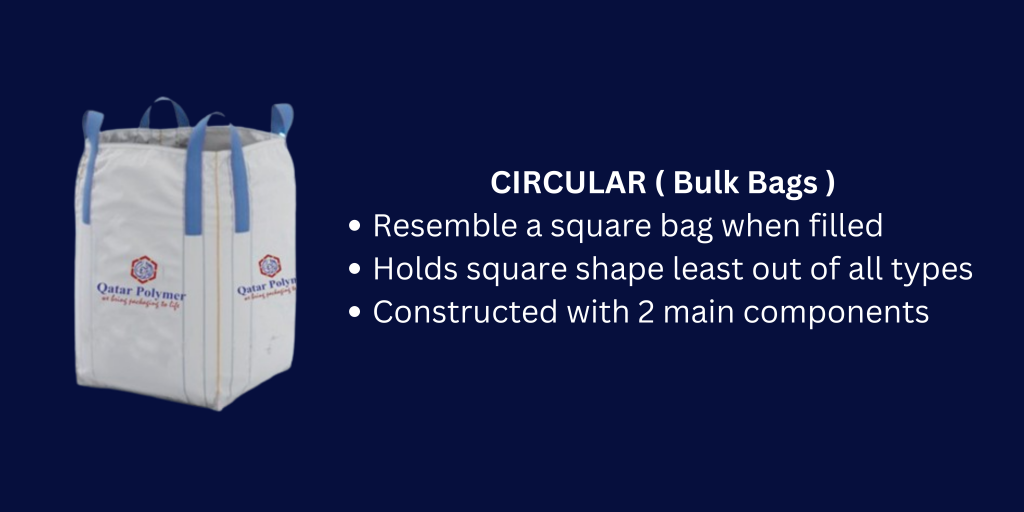

Circular Bulk Bags

Circular bags, also called tubular bags, are constructed with two main body components: the body tube and the base.

The body tube is made with seamless tubular fabric that forms all sides of the bag, allowing for stitching only at the top and base of the bag. Although the fabric is tubular, when filled, a circular bag will still somewhat resemble a square bag.

There is a common misconception about circular bags regarding their shape when filled. They are not truly circular — they are simply constructed with a single piece of fabric that forms all four sides of the bag. While they still resemble square or rectangular FIBCs when filled, they will hold that shape the least out of all the construction types.

4-Panel Bulk Bags

A very common bulk bag style, 4-panel bags are constructed with five main body components: four side panels and the base.

When filled, a 4-panel bag will hold its square shape similar to other construction types. Typically, 4-panel bags will hold their shape better than U-panel bags, while U-panel bags will hold their shape better than circular bags.

Due to the large amount of stitching required, a 4-panel bag has a greater opportunity to fail at the seams and is prone to sifting. Nevertheless, 4-panel bags are ideal for storage due to the way they hold their shape when filled.

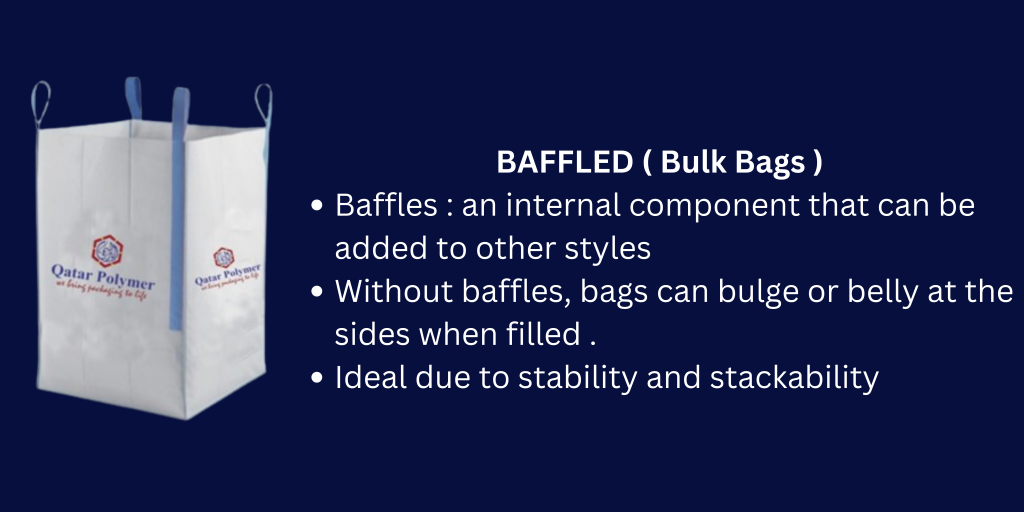

Baffled Bulk Bags

Baffles are an internal component that can be added to a U-panel, 4-panel, or circular-style bag. More specifically, baffles are fabric panels or strings sewn inside each of a bulk bag’s four corners that allow it to maintain a square shape when filled.

Without baffles, the construction types listed above can bulge or belly at the sides when filled.

Also called Q bags, baffled bags are ideal due to their stability and stackability. They also improve overall storage capacity. The most common type of baffled bag is a 4-panel baffled bag.

Which Type of Bulk Bag Is Right for You?

When it comes to bulk material handling, understanding the various types of FIBCs is critical.

Qatar Polymer, manufactures and customize on-demand FIBCs in the country. We can help you choose the right bulk bag type for your business, ensuring that your packaging solutions align with your specific requirements and industry regulations.

For more information about our FIBC stock or to request a quote, contact us today.